-advertisement-

Shin-Etsu Chemical Co., Ltd. (TOKYO: 4063) has introduced advanced equipment for manufacturing semiconductor package substrates using a novel method, building upon their micro-LED manufacturing technology. This equipment employs an excimer laser and the dual damascene method—commonly used in the front-end semiconductor manufacturing—to enhance the back-end process of package substrate production. This innovation eliminates the need for an interposer and allows for greater microfabrication, reducing both costs and capital investment by omitting the photoresist process.

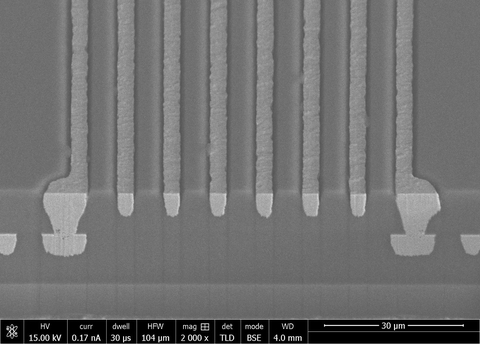

Two-layer sample processed by Shin-Etsu dual damascene method (Cross-section view)

Chiplets, which are smaller, singulated circuit components that are later assembled into a package, have gained traction for their cost-efficiency in producing high-performance semiconductors. Typically, chiplets are mounted on an interposer, an intermediate substrate linking them. The Shin-Etsu dual damascene method removes the necessity for an interposer, simplifying the assembly process. Instead, chiplets are directly connected to a package substrate with wiring patterns that function equivalently to an interposer, thereby reducing assembly time and costs.

The equipment's microfabrication technology enables the formation of intricate electric circuit patterns within the organic insulation layers of a multi-layered package substrate, followed by copper plating. The excimer laser forms large-area electric circuit patterns in batches, achieving miniaturization not possible with the current mainstream semi-additive processing (SAP) method using dry film resist. The laser processing equipment can handle areas of 100 mm² or larger in one go, utilizing Shin-Etsu’s specialized photomasks and lenses. Processing time is consistent regardless of the number of vias, with an example time of 20 minutes to form specific trenches, electrode pads, and vias on a 515 mm x 510 mm organic substrate.

Shin-Etsu Chemical aims to integrate its material and equipment technologies to propose comprehensive solutions for next-generation technologies, contributing to the advancement of a prosperous society.

Editor:Lulu

▼▼▼

KSG GmbH achieves remarkable energy efficiency milestone with sustainable innovations

Daeduck Electronics' Vietnam factory celebrates its 10th anniversary

Notion Systems expands and moves into its new company building

Glass substrates in semiconductor packaging: Opportunities and challenges

Aimtron Electronic Ltd., has recently gone public!

Haesung DS leads the way in supply price linkage, honored as 2023 Outstanding Company

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday