Recently, SD Optics has announced the development of its "TGV Vision Master," an advanced inspection system capable of full-scale testing of Through-Glass Via (TGV) structures—one of the most challenging processes in semiconductor glass substrate manufacturing. As the industry accelerates the adoption of glass substrates, new solutions like this are emerging to ensure commercial viability.

Breakthrough in TGV Inspection Technology

TGV technology involves drilling micron-sized holes in glass substrates and filling them with copper or other metals to enable electrical signal transmission. For optimal performance, these vias must be uniform in size and perfectly aligned, with minimal variation in hole diameter between the top and bottom layers.

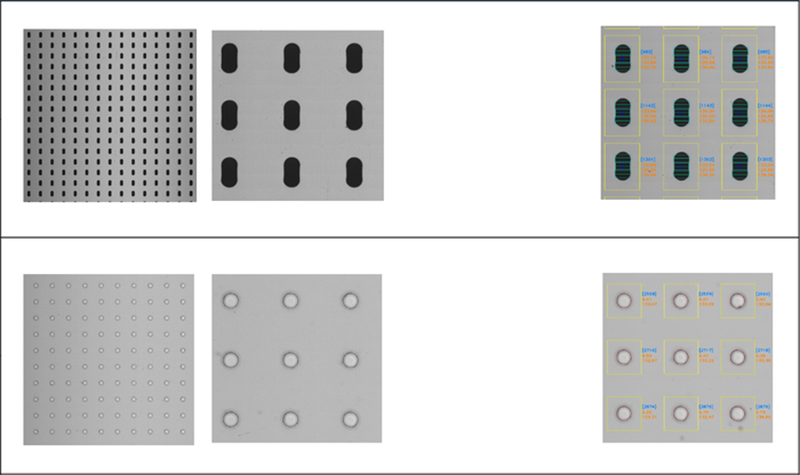

SD Optics' new system uses a 3D optical line scanner to perform real-time TGV inspections. This innovative approach measures the top, bottom, and inner diameters of each via, analyzing its roundness, taper angle, and positional deviations. By instantly detecting microscopic process variations, the system ensures higher production quality and yield for semiconductor glass substrates.

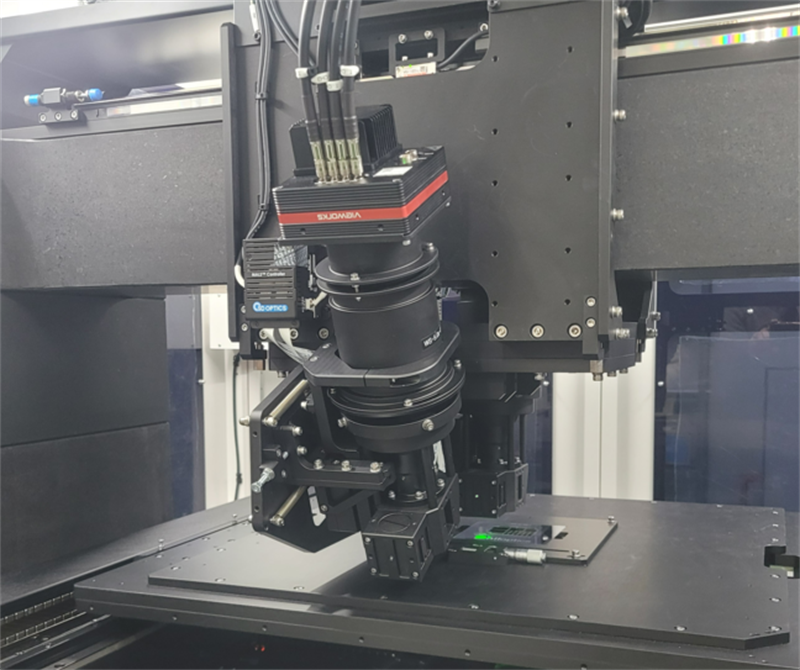

SD Optics' semiconductor glass substrate TGV inspection solution, "TGV Vision Master," inspecting a sample

Industry-Leading Precision and Speed

A key challenge in TGV inspection has been the need for high-speed optical focus adjustments. SD Optics overcomes this with its proprietary Multi-Axis Lens Scanning (MALS) technology, originally developed for Carl Zeiss, a global leader in optics. The MALS system features 8,000 micro-mirrors that dynamically control light angles, allowing for real-time focusing and ultra-precise measurements.

With this technology, SD Optics achieves a scanning speed of 40mm per second, enabling full-scale inspection of large glass substrates measuring 510mm × 515mm. Additionally, the system can simultaneously detect cracks and defects in the upper, middle, and lower layers of TGV holes. Identifying these structural weaknesses early helps prevent breakage during subsequent high-temperature and high-pressure processes, improving overall yield.

SD Optics reports a repeatability precision of 0.25μm, surpassing the industry standard of 0.3μm, ensuring higher accuracy for manufacturers.

SD Optics' inspection image. The system measures the outer diameter, inner diameter, positional accuracy, and roundness (circularity) of the TGV holes in the semiconductor glass substrate. (Photo: SD Optics)

Expanding Inspection Capabilities

Beyond TGV inspection, the system also analyzes post-cut glass substrates, evaluating dimensions, thickness, step height, and defects after the Ajinomoto Build-up Film (ABF) process. This final assessment ensures that individual substrate units meet strict industry standards.

Partnership with Philoptics and Global Expansion

SD Optics is collaborating with Philoptics, a leading PCB and semiconductor glass substrate processing equipment provider, to commercialize this new solution. The system is being developed as an integrated inspection tool, with one key customer already secured and negotiations underway with overseas manufacturers.

Jung Kyung-seok, Chief Strategy Officer (CSO) of SD Optics, emphasized, "This is the first full-scale inspection system designed for semiconductor glass substrate production lines. Compared to conventional individual inspections, it offers superior efficiency and precision. We expect it to significantly enhance process quality and manufacturing productivity."

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday