-advertisement-

Salgenx, a leader in energy storage and advanced materials, has introduced a groundbreaking method for producing low-cost, eco-friendly circuit boards. This innovative process uses graphene and hard carbon-coated materials, which are laser-engraved to create precise circuit patterns and conductive pads. This advancement could transform electronics manufacturing, offering a versatile, sustainable, and cost-effective alternative to traditional printed circuit boards (PCBs).

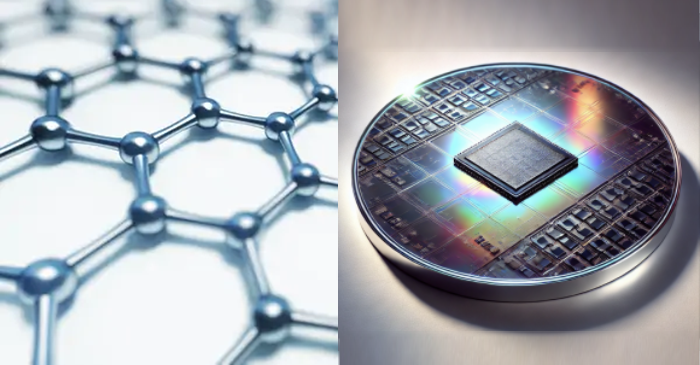

Harnessing Graphene and Hard Carbon

Salgenx’s proprietary process coats sand with graphene and hard carbon, sourced from sustainable materials like sugar and sawdust. These coatings offer exceptional electrical conductivity and strength, ideal for various applications.

Starting with a flat piece of graphene and hard carbon-coated material, Salgenx uses laser technology to engrave intricate circuit patterns directly onto the substrate. This method enables high precision, customization, and minimal waste, reducing the environmental impact of traditional PCB manufacturing.

Key advantages of Salgenx’s laser-engraved circuit boards include:

● Precision and Customization: Laser engraving allows for detailed, customized circuit designs, perfect for rapid prototyping and tailored electronic solutions.

● Reduced Waste and Environmental Impact: Salgenx’s method eliminates many chemical processes used in traditional PCB production, leading to a cleaner, more sustainable process.

● Scalability: The process can be scaled for mass production, providing a cost-effective solution for consumer electronics, wearable devices, and more.

Expanding Electronics and Smart Infrastructure

Salgenx’s technology has potential applications beyond traditional electronics, including:

● Flexible Electronics: The flexibility of graphene combined with laser precision enables new possibilities in foldable smartphones, electronic textiles, and wearables.

● Smart Surfaces and Infrastructure: This approach could lead to smart surfaces with embedded sensors, ideal for interactive displays and integrated technologies in modern infrastructure.

● Energy-Efficient Buildings: Graphene-coated materials could improve thermal management and energy efficiency in buildings while offering EMI shielding for sensitive electronics.

Sustainability and Cost Efficiency

By using sustainable materials and minimizing chemical processing, Salgenx’s laser-engraved circuit boards mark a significant advance in eco-friendly electronics manufacturing. The cost-effectiveness of this technology makes it appealing across various industries, from consumer electronics to advanced manufacturing.

Editor:Lulu

▼▼▼

Intekplus signs supply agreement with Taiwan's largest foundry company for PCB inspection equipment

Aculaser establishes joint venture to enter glass substrate market

LG Innotek struggles to expand in Samsung smartphone CoF market as Stemco leads

STARTEAM GLOBAL adopts Notion Systems'digital n.jet soldermask system

Samsung Electro-Mechanics vs. LG Innotek CEO compensation: Who comes out on top?

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday