Mitsubishi Materials Corporation and Panasonic Corporation announced on January 17, 2025, the successful establishment and operation of a PMP (Product-Material-Product) loop, which recycles gold, silver, and copper from waste printed circuit boards (PCBs) of discarded home appliances, primarily within the Panasonic Group. This marks a significant milestone in the industry's efforts to create a sustainable, circular economy.

The PMP loop, the first (Mitsubishi Materials and Panasonic data as of January 17, 2025) of its kind, has facilitated the recycling of valuable urban mining resources, with a cumulative total of 1.1 tons of gold, 33 tons of silver, and 8,100 tons of copper (Data as of December 2024) recovered. This initiative aligns with the growing global demand for more efficient use of metal resources and environmental protection, especially in Japan, where the self-sufficiency rate for natural resources is low. The Japanese government's Growth-Oriented, Resource-Autonomous Circular Economy Strategy emphasizes the need for sustainable practices to drive both economic development and environmental protection.

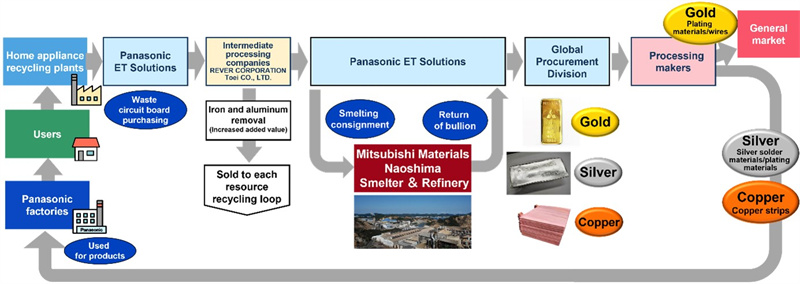

Since its inception in 2011, Mitsubishi Materials and Panasonic have worked collaboratively to smelt waste PCBs collected from home appliance recycling centers across Japan. The extracted gold, silver, and copper are reused in manufacturing within the Panasonic Group and for other applications. This process helps reduce reliance on primary metal extraction and contributes to a sustainable, closed-loop system for valuable non-ferrous metals.

A key environmental benefit of the PMP loop is its contribution to reducing CO2 emissions. For instance, the 8,100 tons of copper recovered through this system, instead of being sourced through traditional smelting of copper ores, has helped to reduce CO2 emissions by approximately 33,000 tons. Additionally, the recovered copper is being used as raw material for copper wires in the Panasonic Group Pavilion at Expo 2025 Osaka, Kansai, showcasing the company's commitment to sustainable practices.

Mitsubishi Materials and Panasonic aim to expand their efforts in end-to-end resource recycling, from collecting waste materials to reusing them in new products. Through the experiences gained in operating the PMP loop, they plan to increase awareness of non-ferrous metal recycling and collaborate with partners to establish new recycling schemes. The goal is to further evolve the circular economy and reduce CO2 emissions on a larger scale.

In this collaboration, Panasonic ET Solutions Co., Ltd. (PETS), a subsidiary of Panasonic, plays a crucial role. PETS manages the collection and initial processing of waste PCBs, separating unwanted iron and aluminum before sending the refined material to Mitsubishi Materials for smelting. The resulting gold, silver, and copper are returned to PETS for use in Panasonic's products, demonstrating the full circular loop from waste to new manufacturing materials.

To date, the PMP loop has recovered a total of 1.1 tons of gold, 33 tons of silver, and 8,100 tons of copper from waste PCBs. These metals are now used in various products within the Panasonic Group, contributing to both resource conservation and CO2 reduction.

This innovative approach sets a powerful example of how large corporations can contribute to the global effort of creating a sustainable and resource-efficient economy. Mitsubishi Materials and Panasonic continue to work towards a more circular, low-carbon future, one metal at a time.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday