We have developed the innovative technology, F-ALCS which maximizes wiring capacity of printed wiring boards. These boards with high wiring flexibility have knocked the bottom out of product development.

F-ALCS ensures highly reliable connections between vias thru paste filling and metal bonding which allow more than two times higher wiring density than before. It is optimal for difficult designs which were previously considered to be impossible.

The 5 common challengesin PCB manufacturing arenow solved by F-ALCS

1. Reduce restrictions in design and enable high performance!

All you have to do is to place vias on a layer only where you need them. This innovation and using smaller via pads make it possible to place parts with less restrictions because they leave a lot more space for mounting and wiring on a printed wiring board. F-ALCS is applicable to large-sized printed wiring boards such as the any layer IVH structure with the maximum seventy-two layers. This means it can hold the same amount of wiring as one hundred forty layers.

Differences in wiring and mounting areas between regular IVH structure and F-ALCS structure

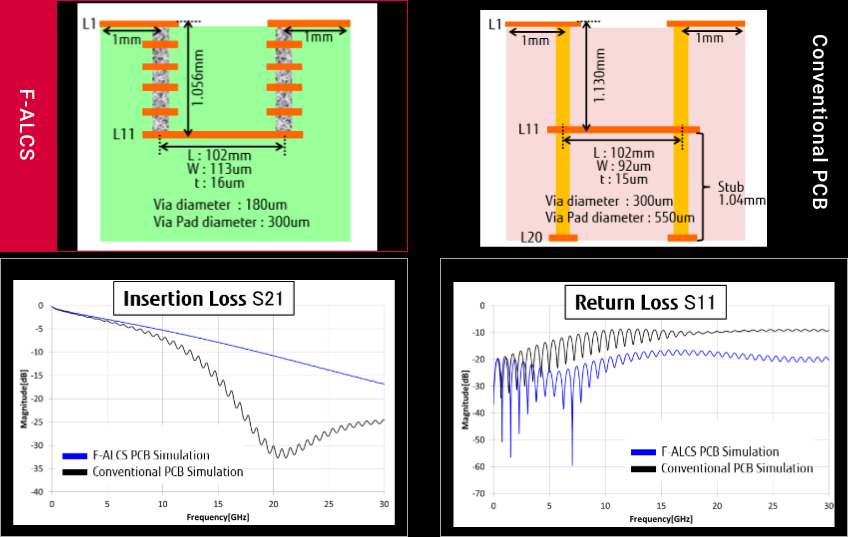

2. Reduce the number of open circuited stubs and perform high-speed signal transmission!

The transmission loss of high-speed signal caused by open stubs is solved by the any layer IVH structure. This reduces return loss and helps printed wiring boards to have good transmission characteristics even for high frequency, which results in high-speed signal transmission.

Transmission Characteristics Comparison betweenF-ALCS and Conventional PCB structure

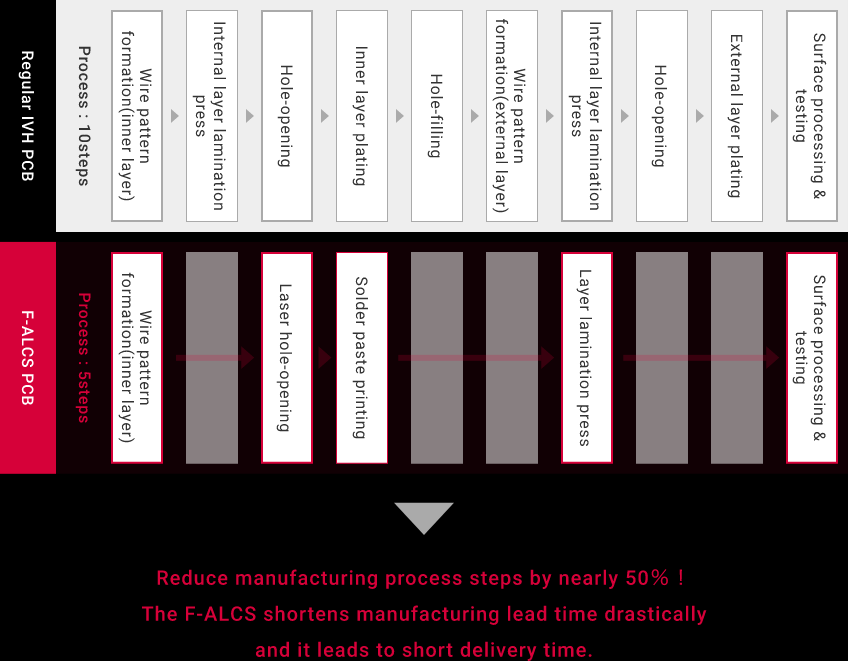

3. Reduce process steps by 50% and shorten delivery time!

By using the any layer IVH with one-time lamination, F-ALCS allows you to decrease the manufacturing process steps by 50%. F-ALCS also reduces restrictions in printed wiring board design which eventually reduces the number of designing process steps. This means it shortens manufacturing lead time drastically and it leads to short delivery times.

Different numbers of process stepsfor regular IVH PCB and F-ALCS PCB

4. Applied to any material and meet a wide range of requirements

F-ALCS allows you to choose from many resins from regular FR-4 to low loss materials. Since it can be used in various ways for various uses, F-ALCS enables printed wiring board manufacturing to meet your needs and expectations.

5. No need to plate and easy on the environment

Because the plating process is not necessary for connecting vias which sometimes requires using toxic substances, printed wiring board manufacturing is easy on the environment. This also enables to shorten manufacturing time.

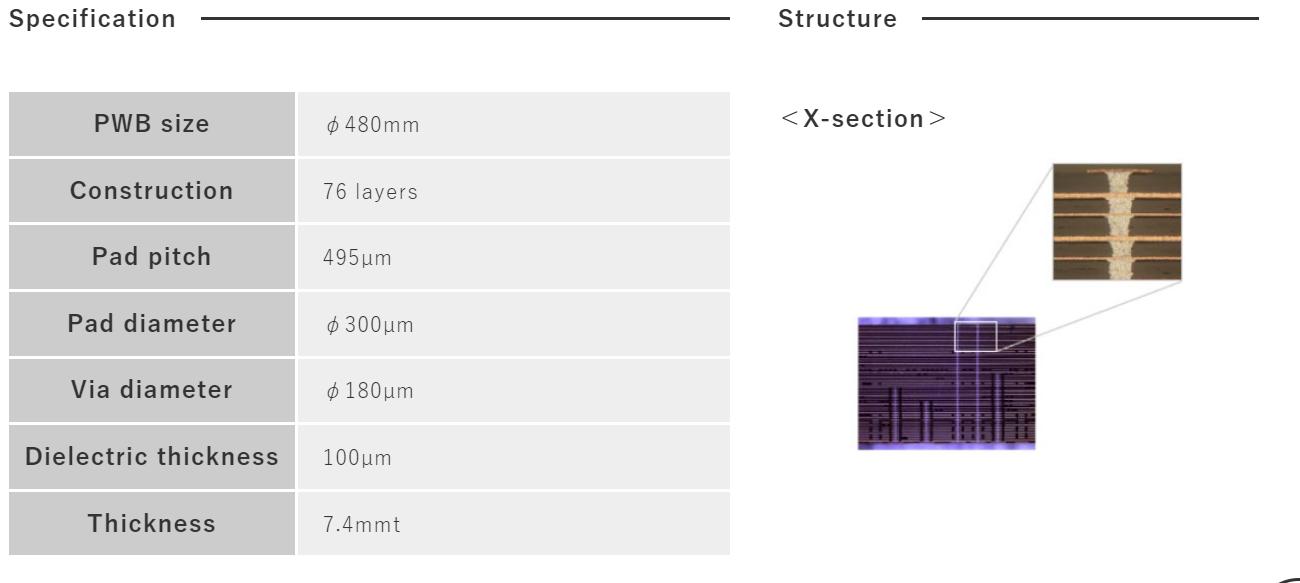

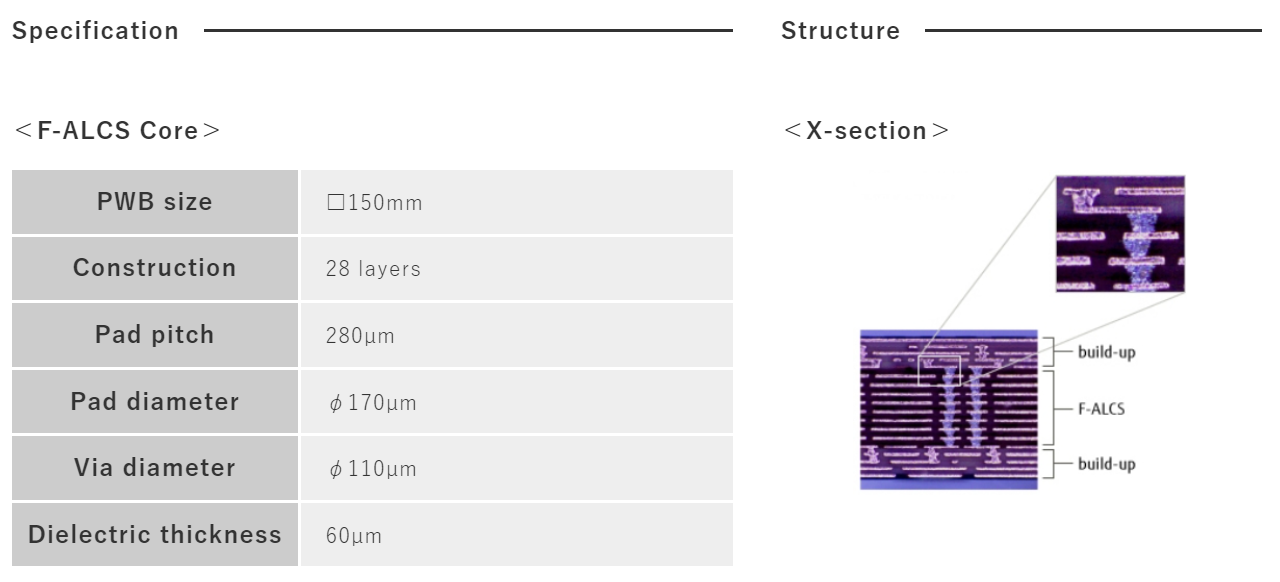

Product outline

1. For high density wiring (F-ALCS)

2. For high density mounting (F-ALCS + build-up structure)

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday