-advertisement-

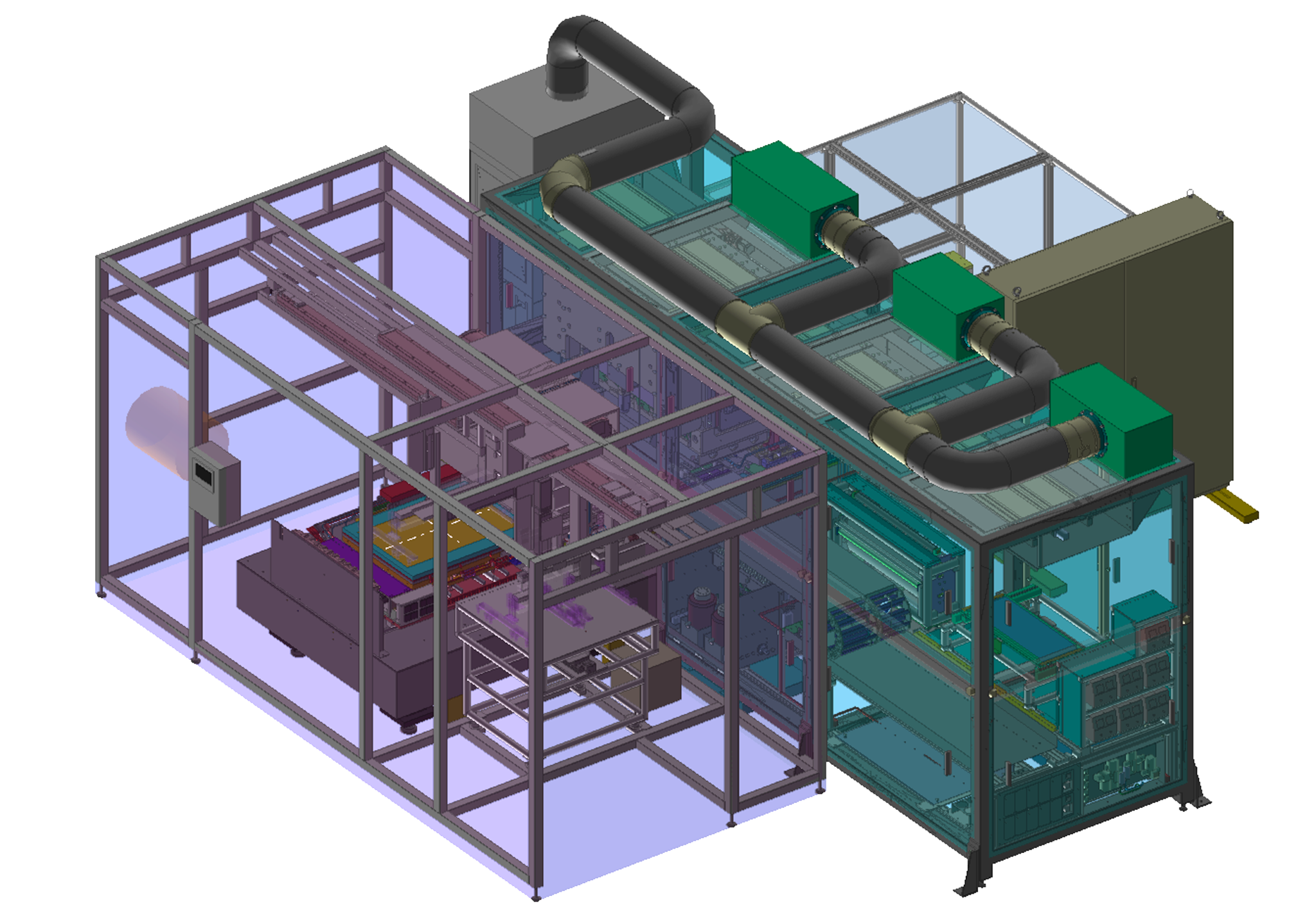

Japanese green tech innovator Elephantech has introduced the "ELP04-PCB," an advanced inkjet printing system designed for large-scale printed circuit board (PCB) production. Building on its extensive experience in mass-producing PCBs, the company has optimized this system to meet the demands of high-volume manufacturing.

ELP04-PCB

Inkjet technology, known for its precision in applying picoliter-sized droplets directly to target areas without contact, has traditionally faced challenges in achieving high-speed, high-precision, and consistent quality, limiting its use in electronics. The ELP04-PCB overcomes these challenges, offering the accuracy and productivity essential for mass production. It also integrates Elephantech's AI-driven "NeuralJet™" technology, enabling precise printing with AI support.

Key Features:

● High-Precision, High-Throughput Inkjet Printing: The system's robust design and long nozzle head array ensure both high precision and productivity.

● Mass Production Expertise: Leveraging Elephantech's PCB manufacturing experience, the system includes maintenance mechanisms for stable ink ejection and employs NeuralJet™ technology for accurate drop placement.

● Modular Design: The platform's modular approach allows for scalable printing systems and customizable modules to meet specific application needs.

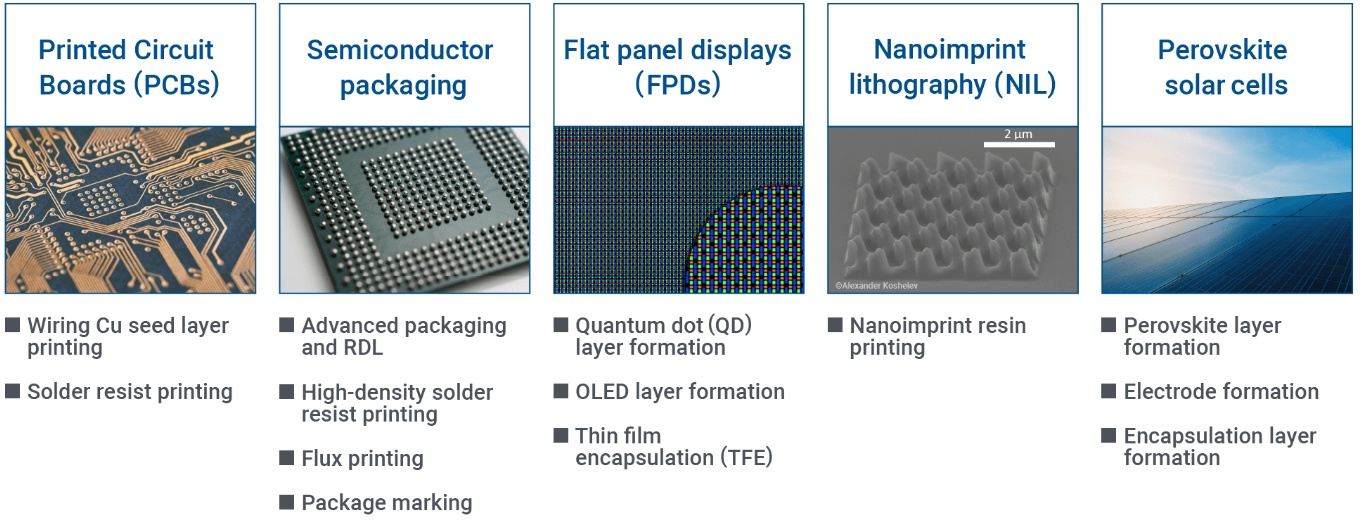

Starting in 2025, Elephantech will use the ELP04-PCB for its own PCB production and market it as a solution for mass production. The ELP04 platform is also gaining interest for applications in semiconductor back-end processes and FPD manufacturing, where precision and productivity are critical.

Applications of the ELP04 Printing Platform

About Elephantech

Elephantech was founded in 2014 and is the world's first PCB manufacturer to successfully use metal inkjet printing technology. The metal inkjet printing technology significantly reduces the environmental impact without affecting product performance, reducing CO2 emissions by 75%, water consumption by 95%, and copper consumption by 70%. The technology has been approved by the Ministry of the Environment.

Editor:Lulu

▼▼▼

E&R Engineering and 14 Taiwanese companies join forces to sdvance glass substrate technology

Unimicron announces merger with subsidiary Subtron to streamline operations and optimize structure

Kingboard Holdings reports interim results for 2024; Revenue increases by 9% year-on-year

North American PCB industry sales down 21.2 percent in July

C&G Hi Tech files patent for core glass substrate technology

Xavis aims to supply glass substrate inspection equipment to Samsung

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday