China's Wuhan Taiziwei Optoelectronics Technology Co., Ltd. has achieved a significant milestone in the semiconductor industry by launching its T150A photoresist product, which has successfully passed mass production validation. This development marks a major step forward in China's efforts to localize semiconductor manufacturing and reduce reliance on foreign imports for critical materials.

The T150A product, which is benchmarked against the industry-leading KrF photoresist series, demonstrates superior performance with a resolution of 120 nanometers in optical lithography. According to the company, the photoresist offers greater process tolerance, higher stability, and superior sidewall verticality during etching, making it highly compatible with post-lithography processes.

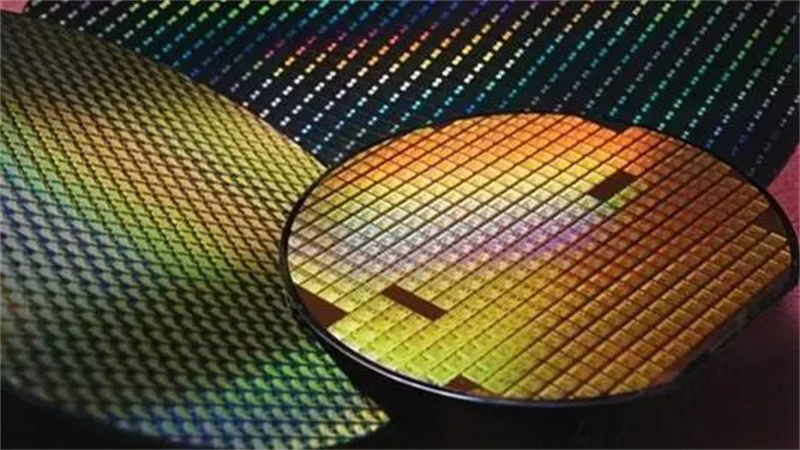

This breakthrough is especially significant because photoresists are essential materials used in semiconductor fabrication. They enable the precise transfer of circuit patterns onto wafers during the photolithography process, a critical step in producing integrated circuits. Historically, China's semiconductor industry has relied heavily on imports, particularly from Japan, which accounts for over 50% of China’s photoresist imports.

Data from China's General Administration of Customs reveals that in 2023, China imported $2.177 billion worth of photosensitive chemicals, with $1.149 billion coming from Japan. The heavy reliance on foreign sources has posed challenges for the country's ambitions to localize semiconductor production.

Despite these hurdles, China's domestic photoresist industry has made rapid progress. While the localization rate for high-end photoresists like KrF and ArF remains low—less than 5% for KrF and 1% for ArF—companies such as Taiziwei are leading efforts to improve these figures. The success of T150A positions Taiziwei as a key player in the push for domestic production and self-reliance in the semiconductor supply chain.

Industry experts acknowledge that while China’s semiconductor sector has grown rapidly in scale over the past decade, significant technological advancements are still needed. Sun Yong, an investment manager in Shanghai, noted that the current phase of semiconductor growth is driven by artificial intelligence and the energy revolution, creating new opportunities for local manufacturers.

As China’s semiconductor industry continues to evolve, leaders like Liu Linfa, director at the Shanghai Integrated Circuit Industry Association, predict that the next decade will bring further innovation in device architecture and the application of new technologies across different sectors. However, they also stress the need for policy support, increased investment, and collaboration between international talent and local industry to overcome challenges and accelerate domestic production.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday