A groundbreaking development from researchers at the Technical University of Dresden (TU Dresden) has created a biodegradable alternative to traditional printed circuit boards (PCBs), offering a potential solution to the growing e-waste crisis. The new approach, dubbed "Leaftronics," uses natural leaf structures to produce flexible, eco-friendly electronic substrates, paving the way for a more sustainable future in electronics.

Tackling the E-Waste Problem

E-waste, now exceeding 60 million tons annually, poses a significant environmental challenge. Circuit boards, which make up to 60% of e-waste by mass, are largely made from non-recyclable materials like fiberglass and epoxy resin. These tough plastics, integral to traditional PCBs, are difficult to reuse or recycle. As a result, most of the world's e-waste ends up in landfills, exacerbating pollution.

With the demand for electronics expected to increase, the need for sustainable alternatives is urgent. Aiming to address this, researchers at TU Dresden, led by Professor Karl Leo and Dr. Hans Kleemann, have developed a new approach that draws inspiration from nature.

The Science Behind 'Leaftronics'

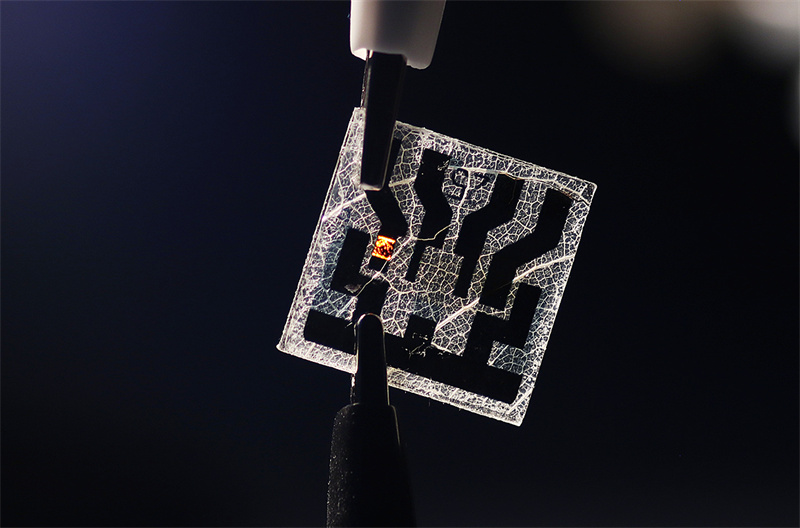

The Leaftronics project utilizes the natural, quasi-fractal lignocellulose structure found in leaves to reinforce biodegradable polymer films. This structure, which supports living cells in plants, is now being used to strengthen polymers without compromising their biodegradability. "We were surprised to find that these natural, quasi-fractal lignocellulosic scaffolds can thermomechanically stabilize polymer films, even at high temperatures," explains Dr. Hans Kleemann.

In practice, the process begins with the extraction of the natural lignocellulose skeleton from a leaf. The researchers then fill the gaps in this structure with ethyl cellulose, a tough biodegradable polymer. The resulting material is strong enough to withstand electronic manufacturing processes like cutting, printing, and soldering.

One of the most impressive results from the team was using a leaftronic substrate to produce organic light-emitting diodes (OLEDs), showcasing its potential in high-performance electronics. Not only do these leaf-based substrates hold up well in production, but they also degrade naturally in the environment. After just a month in a compost heap, the boards begin to break down, offering an eco-friendly end-of-life solution.

A Green Future for Electronics

Leaftronics offers a compelling vision for a more sustainable electronics industry. According to TU Dresden, these biodegradable substrates have a carbon footprint three times smaller than paper, and their production generates significantly fewer emissions compared to traditional PCBs. Furthermore, when discarded, they can be composted, processed in biogas plants, or recycled for valuable materials.

However, as promising as the technology is, the transition from conventional materials to biodegradable leaftronics may take time. Industry experts, like Clara Santato from Montréal Polytechnic, see this as a meaningful step toward sustainable electronics but caution that one technology alone won't solve the entire e-waste problem. "A global problem doesn't have only one answer," she notes.

The biggest hurdle for the widespread adoption of Leaftronics will likely be industry standards. While the materials performed well in laboratory tests, their biodegradability might not meet the durability requirements of current regulations, which are based on traditional materials. "It's more about the willingness of the industry to change," says Dr. Kleemann.

A Glimpse of the Future

Despite these challenges, Leaftronics represents a promising step toward greener electronics. As the world moves toward circular economies and more sustainable manufacturing practices, technologies like Leaftronics offer a glimpse of a future where electronics can be both high-performance and environmentally friendly.

In the future, researchers envision a system where electronics are produced and recycled sustainably—potentially involving tree farms that supply the raw materials for the boards, which are then recycled or decomposed to produce fuel or generate other valuable resources.

As the technology continues to evolve, Leaftronics could play a key role in reshaping how we think about electronics and waste, offering a path toward reducing the environmental impact of our increasingly digital world.

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday