SHINKO ELECTRIC INDUSTRIES CO., LTD. (TSE:6967,SHINKO) announced that its capital investment plan for the manufacturing of next-generation flipchip type packages (FC-BGA substrates) for cutting-edge semiconductors at its Chikuma Plant, located in Chikuma City, Nagano Prefecture, has been certified as a “Supply Security Plan” by Japan’s Minister of Economy, Trade and Industry, based on the Act on the Promotion of Ensuring National Security through Integrated Implementation of Economic Measures. As a result of this certification, subsidies will be granted for the capital investment plan at the Chikuma Plant.

With the spread of 5G, the increasing use of AI and IoT, and the progression of Digital Transformation (DX), etc., society and the economy are becoming digitized. Consequently, the applications for semiconductors are expected to keep growing, further increasing the demand over the medium-to long-term. The market for cutting-edge semiconductors, particularly used for servers and other applications, is projected to expand significantly, driving increasing demand for semiconductors with higher functionality and speed as well as power saving.Demand for more advanced FC-BGA substrates that meet these needs by achieving larger size, higher multi-layering, and ultra-high density fine wiring is expected to increase dramatically.SHINKO is actively engaging in the development of next-generation FC-BGA substrates, including i-THOP®, to capture these needs. By establishing a mass-production system at our Chikuma Plant, we will contribute to the creation of a more affluent society through the advancement of the semiconductor-related industries, realization of Green Transformation (GX) and other factors.

SHINKO's President, Susumu Kurashima, made the following statement regarding the certification:“We are grateful for the support from the Japanese government. FC-BGA substrates are becoming more and more important in high-performance semiconductors, which are driving the digitalization of society and the economy, and are playing a pivotal role in semiconductor evolution. In the cutting-edge semiconductor market, there is a demand for FC-BGA substrates that greatly surpass conventional performance through larger size, higher multi-layering, and ultra-high density fine wiring technology. By stably producing in Japan and launching nextgeneration FC-BGA substrates, including i-THOP® developed by SHINKO, we will contribute to the development of semiconductor-related industries and Japan’s economic security.”

Outline of supply security plan, as planned

1) Name of the operator

Shinko Electric Industries Co., Ltd.

2) Investment amount

53.3 billion yen(approximately $382 million)

3) Maximum subsidy

17.8 billion yen(approximately $128 million)

4) Facility

Chikuma Plant

5) Main products manufactured

Next-generation FC-BGA substrates

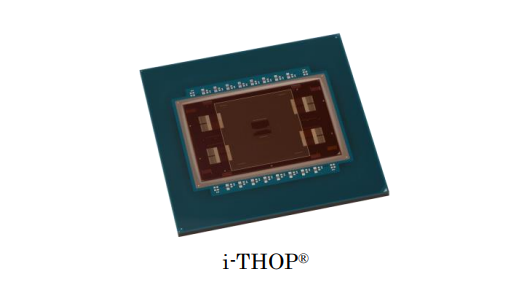

[About i-THOP®]

“integrated Thin film High density Organic Package (i-THOP®)” developed by SHINKO is an FC-BGA substrate that assembles an ultra-fine wiring layer formed through high density wiring technology and thin-film technology with a build-up substrate. The ultra-fine wiring layer of i-THOP® enables the assembly of multiple logic chips and heterogeneous integrations, such as logic chips and high bandwidth memory (HBM). SHINKO will be introducing i-THOP® to the market as a next-generation FC-BGA substrate that meets the needs of the high-performance computing (HPC) market, which is expected to experience significant growth in the medium-to long-term. i-THOP is a registered trademark of SHINKO ELECTRIC INDUSTRIES CO., LTD.

Additionally, it's worth mentioning that SHINKO obtained the IATF 16949 Certification, an international quality management system standard for the automotive industry, for the design and manufacture of plastic BGA substrates for semiconductor memory. Automotive semiconductors are in high demand as key components in-car electronics, and SHINKO’s plastic BGA substrates are used as highly dependable semiconductor package substrates for automobiles.

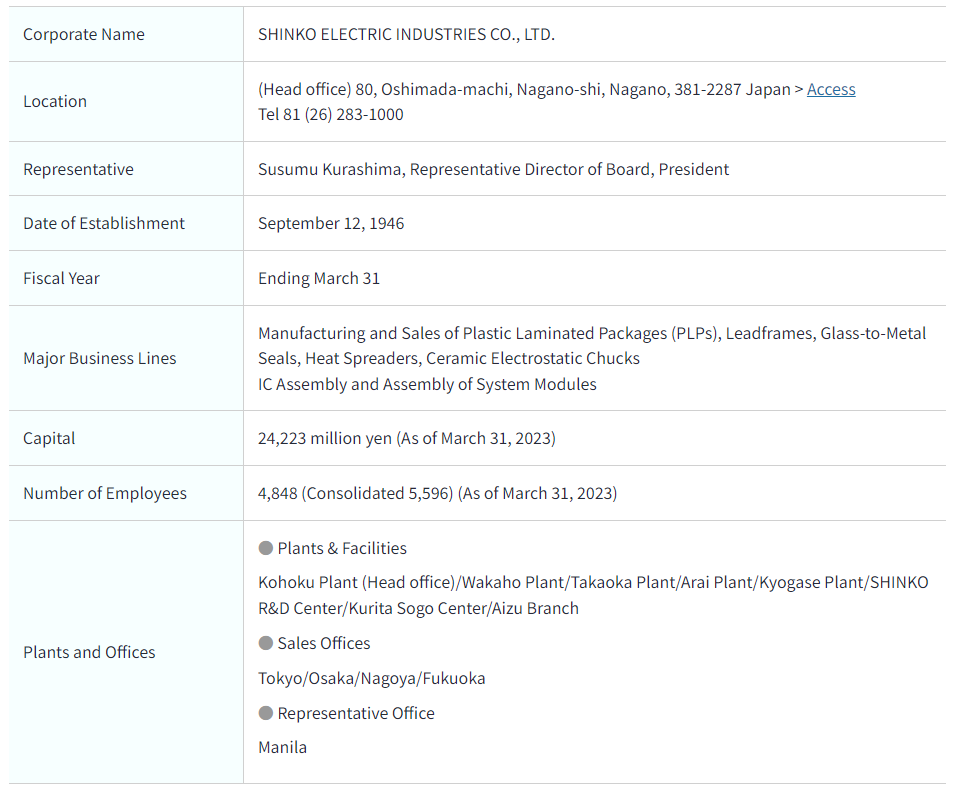

About SHINKO

+86 191 9627 2716

+86 181 7379 0595

8:30 a.m. to 5:30 p.m., Monday to Friday